Really ready to use? Disposable drug dispensers in the X-ray flash

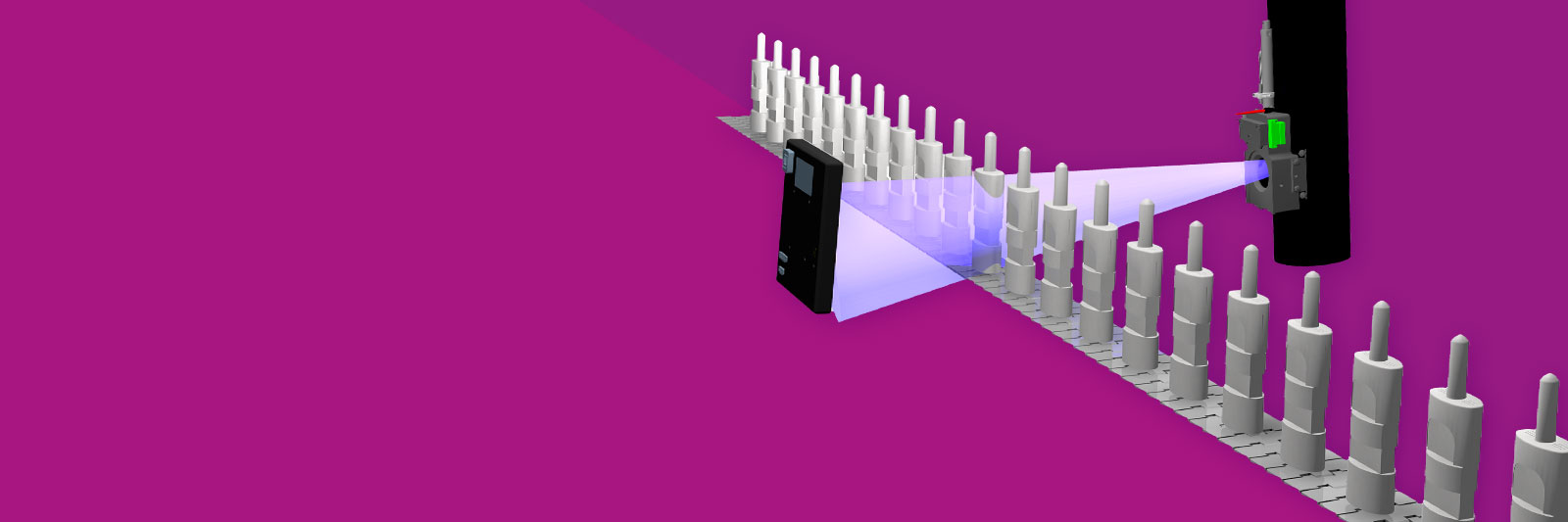

The HEUFT eXaminer II XS checks the completeness, functionality and integrity of special disposable applicators for an uncomplicated and precise nasal drug administration using pulsed radiometric technology.

The compact HEUFT eXaminer II XS for a lateral inspection with pulsed X-rays is increasingly in demand by pharmaceutical manufacturers due to its high level of detection and rejection reliability. Because above and beyond a careful and precise foreign object detection it is optimally suited for a wide range of different applications, particularly in this sector, in order to safeguard product and packaging integrity.

A good example of this is its successful integration at a multinational manufacturer of generic drugs and licensed medicinal products in the USA where special disposable dispensers are filled with life-saving liquid preparations. These ready-to-use applicators make a particularly reliable, precisely dosed nasal administration possible especially in emergencies when every second counts – and they have such a rapid effect that they can completely replace an injection by a healthcare professional: patients can use them quickly and easily to take care of themselves without anyone else's help in the event of an emergency. But only if their completeness, functionality and integrity have been guaranteed. This is exactly what the HEUFT eXaminer II XS checks at the end of the pharmaceutical production line.

Pulsed X-ray inspection and accurate fault rejection

It makes visible what the human eye is no more capable of recognising than camera-based technologies using just one X-ray strobe for a lateral inspection: the complete inside of the opaque disposable nasal spray doser which consists of an actuator, a cannula and a filled glass cartridge sealed with a rubber stopper. It is noticeable directly during the real-time analysis of the high resolution X-ray images with the HEUFT reflexx A.I. image processing if one of these elements is missing.

Misaligned cannulas, incorrectly positioned stoppers as well as incorrectly filled, already emptied, broken cartridges or those contaminated with glass splinters are, among other things, identified just as reliably. The products in question are tracked with millimetre precision in order to be finally sorted out by a HEUFT mono rejector and aggregated on a collection tray.

Successful acceptance and reliable fault detection during running operation

Up to 12,000 units are filled along the line every hour which do not have to be spaced apart – the careful and precise radiometric lateral inspection of each and every one of them as well as the accurate rejection of those detected as faulty works perfectly even when they are close together on the conveyor.

What already emerged during the virtual factory acceptance test of the HEUFT eXaminer II XS during which the customer was connected live all the time from the United States has now also been confirmed after several weeks of operation: filled disposable dosing units which are not ready for use when it counts are identified carefully and precisely by the compact turnkey solution which meets FDA, GMP and GAMP5 requirements – and ensures that they cannot reach the patient in the first place.