Leakproof, pure and uncontaminated

An innovative solution based on the HEUFT SPECTRUM II safeguards the hermetic seals on vials filled with injection liquids. Its special design allows unrestricted use in hygienically sensitive laminar flow areas.

There's no way around it: it is absolutely essential that medicinal products to be parenterally administered are manufactured and filled under clean room conditions. This is the only way that a defined environment with sterile, particle-free air can be ensured for microbially safe end products. Vials must not leave the hygienically demanding area until they have been hermetically sealed. Consequently the integrity of the closure elements also has to be checked here. Indeed it is already too late if a leak is only noticed afterwards: there is a risk of dangerous recontamination - the medicinal product safety is at stake.

A timely closure inspection of freshly filled vials with liquid contents is therefore essential. But does an appropriate solution exist at all which achieves this and may nevertheless be carried out under laminar flow conditions? Yes, a new product for checking the stopper position based on the highly automated HEUFT SPECTRUM II platform. Its design is – as always with HEUFT – strictly linear, free of change parts and so compact that an uncomplicated integration in a confined space is possible. But that is not all: at the same time the hygiene-optimised construction has no components whatsoever projecting above the conveyor where the vials which have not been finally sealed are being transported. Therefore nothing can fall into them or swirl, that is, disturb the laminar flow; the product is protected when being inspected for contamination. The specific rejection of vials with missing stoppers or those which are incorrectly positioned and therefore cannot be hermetically sealed is implemented by a solution developed in-house particularly for hygienically sensitive environments: the HEUFT e-mono carries this out completely without compressed air.

Specific detection in the laminar flow area

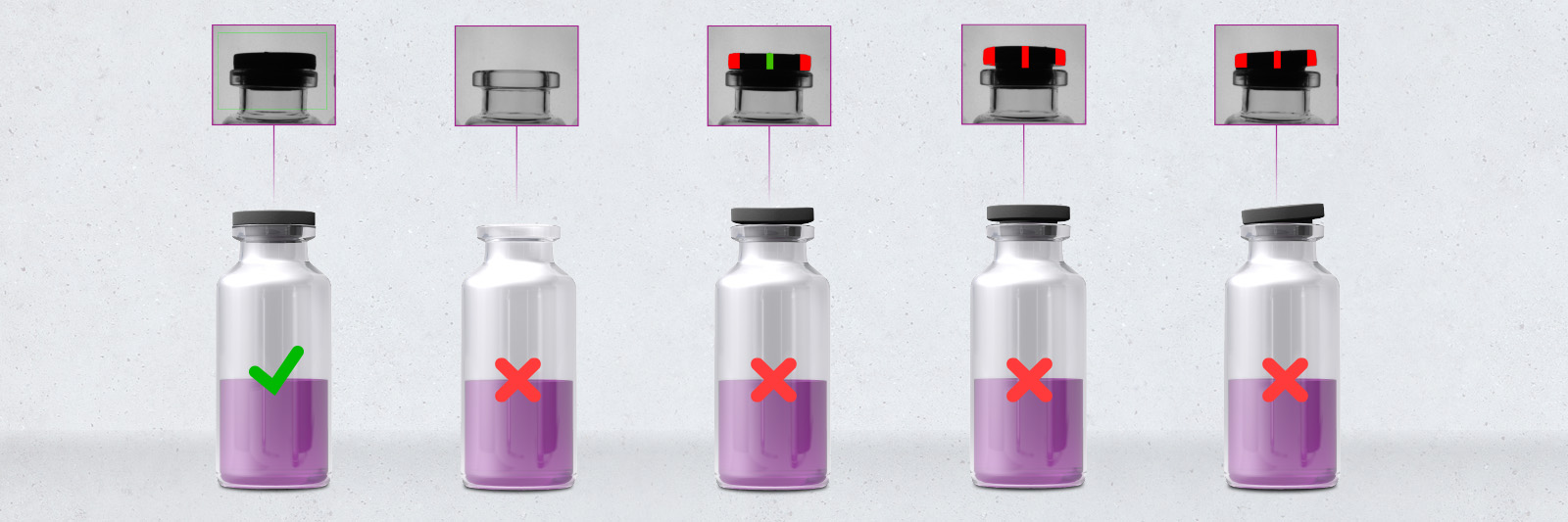

But a specific fault detection takes place before the fault rejection. An intelligent sensor camera with integrated image processing system developed by HEUFT carries this out. Securely integrated into a compact protective casing specially designed for use in laminar flow areas it photographs the profile of the head area of each individual pharmaceutical container so that its contour is plainly visible in the high-resolution photographs. Therefore it can be clearly seen even before the crimp cap is applied whether the rubber stopper is already present and in exactly the correct position. The vial in question is consistently sorted out if on the other hand it is missing, has not achieved the intended end position or is canted. Because then in case of doubt the cap can no longer be correctly crimped, there are dangerous gaps and the microbial purity of the sensitive contents is at risk.

The way then only remains open for the vial containing two, six or fifteen millilitres where the rubber stopper is correctly positioned. Because these can be safely provided with crimp caps and sealed afterwards. It is already immediately clear in the laminar flow area to the new development based on the HEUFT SPECTRUM II which these are. The exceptional degree of automation and the self-explanatory HEUFT NaVi user guidance ensure maximum detection, operating and manipulation safety. The result: pure, uncontaminated medicinal products in impenetrably sealed primary packaging material!