X-ray revolution at FachPack

HEUFT will be presenting two new X-ray systems at the same time at FachPack 2015 in Nuremberg. Both inspection devices revolutionise the in-line detection of foreign objects, product and packaging faults with consistently further developed pulsed X-ray technology and simply more performance. Additional resource saving solutions for the accurate equipping and continuous traceability of primary packaging can be experienced on Stand 3-127 in keeping with the focus topic "Marking & Labelling".

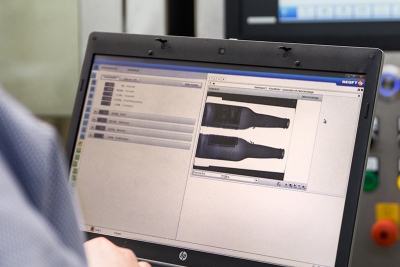

The HEUFT eXaminer II XAC and the HEUFT eXaminer II XB will take the reliable identification of foreign objects, product and packaging faults to a completely new level. The powerful HEUFT SPECTRUM II device platform with its self-explanatory HEUFT NaVi user guidance ensures this. However the innovative technology for a pulsed X-ray inspection is truly revolutionary:

an unprecedented combination of unique X-ray strobes and special image converters makes the complete inspection of larger products and packaging a reality. The size of the faults which can be reliably identified is halved at the same time regardless of whether minute glass splinters, metal fragments, pieces of plastic, product incompleteness or packaging defects. And all this with unequalled low radiation.

Revolutionary performance for maximum safety

In contrast the high speed is unsurpassed: 1,200 products can be examined by the HEUFT eXaminer II XB for the top-down inspection of pouches, flow packs and solid products as well as with the new HEUFT eXaminer II XAC for an extensive full container inspection. Its HEUFT CleanDesign designed for optimum hygiene offers no opportunity for the accumulation of dirt and makes the cleaning of the compact end of line systems easier. However the consistently further developed pulsed X-ray technology for simply more detection reliability is revolutionary.

The same is true of an innovative system solution for the continuous traceability of primary packaging which HEUFT will be presenting at FachPack. It verifies product and batch data stored in 2D matrix codes in-line. In addition it carries out the GS1 compliant grading of the coding, which is hardly visible to the naked eye, itself. All this is possible even in the case of containers which have not been specifically aligned. The respective whereabouts of each individual container can be accurately traced at any time due to permanent real-time monitoring and a complete process and product data backup. The result: a hundred per cent traceability.

Furthermore a wet glue labelling station equipped with an automatic magazine feed (AMF) can be experienced on the HEUFT exhibition stand. This ensures a higher stock of labels and reduces the need for manual intervention. This avoids costly standstills and saves human resources at the same time.

Join the revolution: FachPack 2015 / 29 September to 1 October / Stand 3-127 / Nuremberg