Precise shoulder view when inspecting empty cans

The further developed HEUFT canLine II with its new connectable add-on module now achieves full coverage during the in-line inspection of beverage and food cans before the filling process.

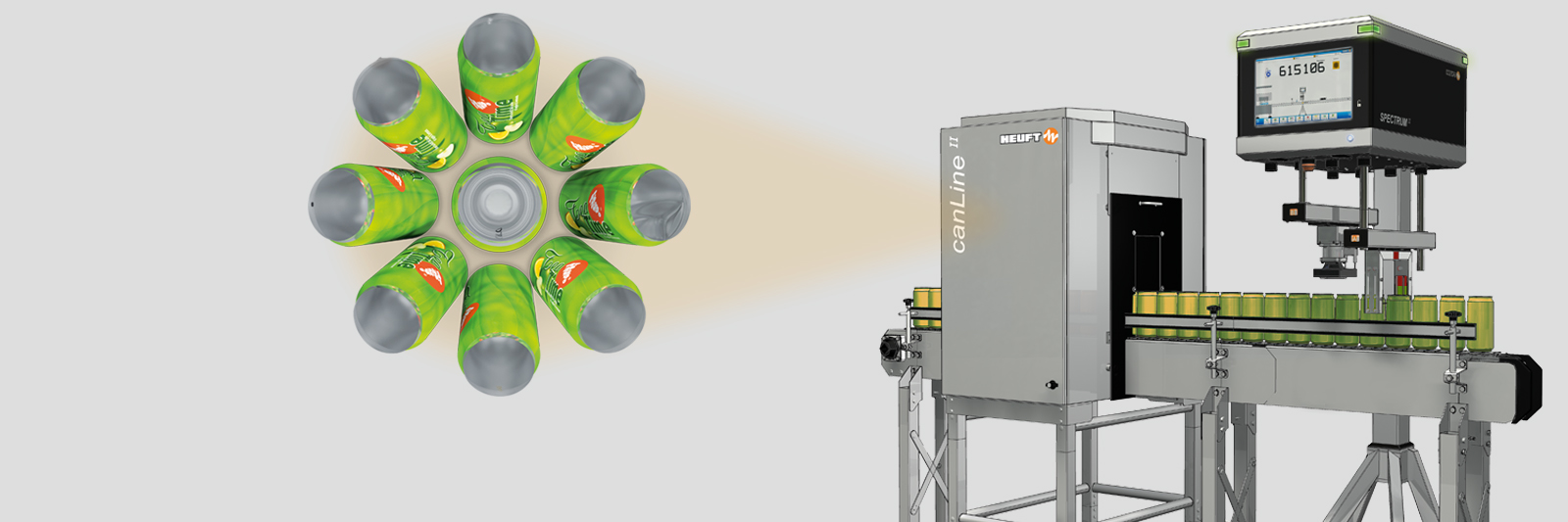

Identifying deformations and defects at the flanged edge of the finish of empty cans just as reliably as soiled or dented inner walls or contamination and foreign objects on their base – the compact HEUFT canLine II carries out all this with only one intelligent top-down colour sensor camera. The new generation system launched on the market last year can now be extended by a further detection unit in order to ensure that the empty can inspection also completely covers the hardly visible, bevelled shoulder area of the inner top sidewall just below the can opening:

The safely enclosed optical add-on module directly at the conveyor, which is based on the HEUFT FinalView II CAP technology for a 360° closure inspection of full containers, generates a total of eight high-resolution camera views each from exactly the right perspective which reproduce the sensitive area below the flanged edge of each individual can completely. Even the smallest amount of damage, residue or contamination such as material flaws, lacquer faults, residual oil or grease and marks are identified there reliably – in combination with the in-house developed HEUFT reflexx² technology of the new generation for real-time image processing. In fact even with minimum distance between the individual containers on the conveyor.

More packaging safety and productivity

The standard top-down empty can inspection with in-house developed colour sensor camera including fully integrated image converter technology and adaptive LED lighting covers the flanged edge, the remaining inner wall areas and the base of the can – and achieves such a depth of field that neither deformations, defects and dents nor contamination and foreign objects can be overlooked: food or beverage cans which cannot be reliably sealed are identified and rejected just as reliably as faulty and contaminated ones. In this way the HEUFT canLine II prevents obstructions in the closer which slow down productivity and protects the safety of the filled end product at the same time.

The higher-level HEUFT SPECTRUM II platform, on which the HEUFT canLine II is based, offers a maximum degree of automation and support for the user: the height and the LED lighting of the intelligent colour sensor camera is adapted to the new container format during brand changes just as automatically as the passage width of the guide rails in the inspection area. The HEUFT NaVi user guidance provides the operator with audiovisual step-by-step assistance which makes every change self-explanatory. The innovative adaptive LED lighting which is directly integrated in the sensor camera also adjusts completely automatically to the changed brand.

A new dimension in detection and rejection reliability is achieved with the clear advantage in terms of automation, computing power and precision when tracking HEUFT SPECTRUM II systems have to offer.