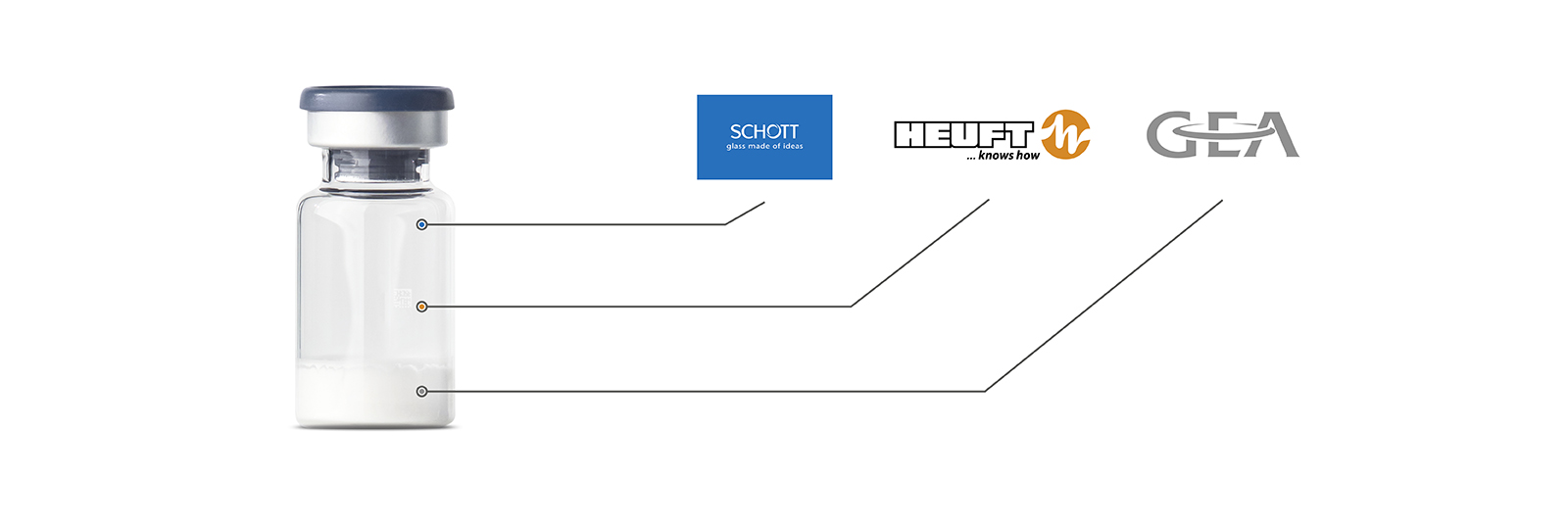

Cumulative expertise for unique traceability

A complete solution from SCHOTT, HEUFT and GEA ensures the unique marking, clear identification and consistent traceability of pharmaceutical primary packaging. Therefore drug counterfeiting is practically impossible.

The clock is ticking: the Directorate General for Health and Food Safety of the European Commission will be publishing the delegated acts at the end of the year. Pharmaceutical manufacturers will only have time then until 2018 to implement the requirements of the EU counterfeiting directive and to ensure an end to end verification of the authenticity of drugs. A new type of system solution for the continuous traceability of primary packaging, including a complete process and product data backup, makes an important contribution here.

It ensures unmistakable marking and the one hundred per cent traceability of pharmaceutical products in vials and similar full containers from laser coding and code verification, grading and freeze drying up to the finished final product. This prevents drug counterfeiting and therefore not only protects the holder of the trademark rights but also the health of the patient.

Unique marking and clear detection

SCHOTT lasers a 2D code into the glass body during manufacture, which is in accordance with ISO/IEC 1515 and 16022 standards, without having an adverse effect on the quality of the small pharmaceutical bottle due to microcracks, glass defects or a loss in mechanical stability. An innovative HEUFT module for the optical all-around inspection of the containers then checks the subtle GS1 coding – it is suitable for oRABS, cRABS and isolators and is very easy to integrate into the automatic ALUSTM load and unload systems for GEA freeze dryers with loading speeds of up to 500 vials per minute.

Each individual vial is subjected to a complete all-around examination there – before and after lyophilisation. The optical inspection includes the verification of the contents of the stored product and batch data as well as the code grading in accordance with ISO/IEC 15415. In addition a fill quantity and stopper position check as well as the detection of glass defects are possible. Full detection reliability is always provided even when the containers are not aligned. A special HEUFT rejection system removes them, without the use of compressed air, from the production flow if they are faulty. Thus the solution meets the high class A clean room standards. Its mechanical design allows unrestricted use in laminar flow areas.

Permanent monitoring and full traceability

The actual position of each individual coded container can be determined with millimetre accuracy at any time due to permanent monitoring. The result: perfect traceability throughout the entire process chain. Comprehensive real-time data management ensures the efficient transmission, reliable serialisation and sustainable archiving of the verified unique identifier and batch data.

The cGMP and GAMP compliant complete solution from SCHOTT, HEUFT and GEA helps pharmaceutical manufacturers to implement EU directives and to prevent drug counterfeiting effectively.