Precise self-testing at a stable level

New, extremely durable special containers manufactured in-house optimise the implementation of the test programs of HEUFT devices for regularly checking the detection performance when inspecting the fill level in beverage cans.

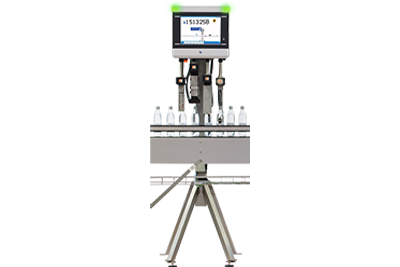

Those who have a checking or inspection system along their filling line also want it to work reliably and always carry out exactly what it is supposed to: detect quality defects precisely and remove the products and packaging in question accurately from the production flow. It should not go unnoticed if the detection and rejection reliability gradually diminishes over time! Otherwise the risk of products with safety and quality defects reaching the end consumer undetected is too high. The HEUFT systems with their patented self-testing functionality provide effective prevention:

they feed test containers prepared with typical faults into the filling line during operation. The devices then have to prove themselves whether they really detect and reject them in each case. Of course these completely logged test container programs also provide clear results when it comes to putting the reliability of the fill level detection for beverage cans through its paces. And HEUFT now also additionally supports the fillers of the metal packaging with thin walls in keeping the condition of their test containers stable and wear-free at all times with specially manufactured test cans in order to ensure consistent test conditions for every test run. Their use also helps to increase the productivity of the entire line and to significantly shorten brand changes.

Durable test cans for full safety and efficiency

It can be freely and individually determined when and in which cycle the test can programs for the full container check and fill management systems from HEUFT are started. However it is more than advisable to always initiate a self-test each time the stock keeping units (SKUs) are changed e.g. from 0.33 to 0.5 litre beverage cans. Because this is the only way to check whether the X-ray measuring bridge for the fill level detection has correctly adjusted its height and position to the changed fill volume and also provides precise results for the changed format of the SKUs. And this is best done with stable test cans which can be used again and again without denting or wearing out over time.

That is why HEUFT makes them for its customers exclusively in solid hard plastic. This eliminates the risk of the test cans losing their shape and resulting in incorrect adjustments to the fill level detection. A precisely adjustable metal piston inside simulates the filling quantity contained. It stays permanently at the required level once it has been set and fixed by means of a small pin. The green ring on the sturdy test can then marks the correct and the red the incorrect fill level. Depending on which of the two is currently up, this simulates either a properly filled or an incorrectly filled container. It is so stable and durable that new test cans do not have to be produced and prepared every time which extends the time required for brand and program changes unnecessarily. Instead line stops and production interruptions are less frequent and also significantly shorter.

Reliable verification of the detection performance

The test can program with the newly available containers manufactured by HEUFT is also simply more efficient because only one of them is required for each SKU in order to check the functionality of the fill level detection regularly under real filling conditions and thus prevent faulty production with entire batches of incorrectly filled beverage cans. Incorrect fill level detection settings and a gradual loss of detection and rejection reliability are detected early enough – preventive maintenance can be initiated in time. And the performance of the test can programs remains at a stable level permanently with the robust new containers!