Strengthening reusability: ‘Best-case scenario’ thanks to new crate inspection!

In the circular economy in particular, it is essential that secondary packaging is free of defects and can be reused without any problems. In order to check its integrity and functionality even more effectively, HEUFT is launching a new generation of modular systems for inspecting empty and full containers at drinktec. One highlight of the device series is the HEUFT HEUFT logic II LR, which ensures that returned reusable beverage crates can be unpacked and distinguishes the containers they contain from one another. This means that only empty cases whose contents actually match the type being processed remain in the production flow.

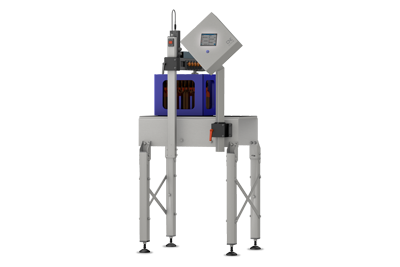

For full crate checking, the space-saving HEUFT logic II LS checks returnables filled with bottles for completeness immediately after the packer. It checks whether their height profile is correct and whether they are gapless and filled with the correct full goods. To ensure absolute brand purity, it can also check the crate logos on the outer walls of each individual container and even the EAN and UPC codes applied to the packaging.

None of this is a problem for the HEUFT logic II LF. In addition, the new full crate inspector, based on the highly automated HEUFT SPECTRUM II, uses HEUFT reflexx A.I. cameras to verify the presence and correctness of the containers. And with X-ray-based inspection of cartons filled with full containers, it detects protruding carton flaps so that only correctly sealed outer packaging reaches the retail trade.

Empty crate inspection for greater line efficiency

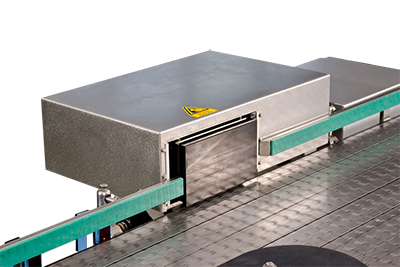

The new HEUFT logic II LR for empty case inspection, which will be unveiled to the public in mid-September at drinktec, stand B4 121 / 321, is at least as powerful. Immediately behind the depalletiser, the modular system uses 3D lasers to check the height profile and geometry of returning reusable beverage crates and identifies those that are warped, cannot be unpacked and cannot be safely reused.

Using intelligent HEUFT reflexx A.I. cameras, it simultaneously examines the interior of each individual crate and, thanks to majority detection, identifies those that are too heavily mixed with empty foreign bottles. To do this, it not only distinguishes between container height and colour, but also between individual container characteristics visible above the compartment dividers, such as contour or closure type. The timely rejection of affected empty crates using particular systems such as the HEUFT maxi-laner ensures the efficiency and productivity of entire filling and packaging lines in the long term.

Empty case inspection to prevent blockages

Installed behind the case washer, the HEUFT logic II LR with the same detection modules performs other important tasks to improve product quality and efficiency in returnable lines: it takes a closer look at the empty beverage cases and detects faults and defects before they cause blockages in the packer and the associated production interruptions.

The identification and rejection of faulty secondary packaging also ensures that only those cases that meet the individual requirements of the respective filler in terms of quality and usability reach the point of sale. Based on the highly automated HEUFT SPECTRUM II platform and with self-explanatory HEUFT NaVi user guidance, the new HEUFT logic II LR implements brand and programme changes quickly, error-free and completely without manual intervention.

Just like the other new HEUFT logic II systems for checking and in-line inspection of already filled full crates, the drinktec trade fair innovation makes a valuable contribution to full quality and efficiency in the circular economy.