Tethered cap inspection without dead angles

On 3 July 2024, EU Directive 2029/904 came into force, making tethered caps mandatory on single-use PET bottles.

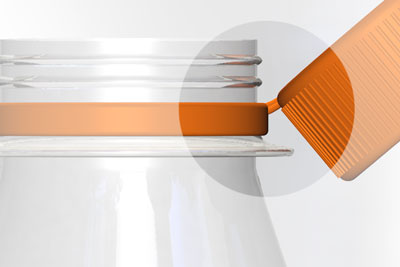

Full closure safety all round! In order to guarantee the reliability required for the most varied types of tethered closures we have long ago made the HEUFT FinalView II CAP fit for special challenges in the optical tethered cap inspection:

An upgrade to the software has since made it possible to roll out four individual camera shots of asymmetrical tethered caps to form a 360° view. This ensures complete coverage. New lighting hardware facilitates all-round inspection of the tamper-evidence bands of rPET bottles. And our advanced closure angle detection reliably checks whether they are correctly and tightly closed.

After all, it is not only the closure type that influences the detection reliability. What matters most of all is sophisticated inspection technologies! The more accurate they are, the more precise the results.

Full coverage, tripled detection accuracy

Transmitted light is a suitable method for detecting defects on the tamper-evident band of all types of closures. Combined with a realistic frontal inspection in incident light, however, much more is possible, especially in the case of asymmetrical tethered caps. Protruding hinges and unusual gaps in the tamper-evidence area then no longer lead to false rejections and the rotational asymmetry of some of them can even be calculated exactly with the intelligent HEUFT reflexx A.I. image processing.

It is also relevant for the quality of the detection whether black and white or colour cameras are used and in what number they are applied. Where it was usual to generate only one view four colour cameras can now be integrated into the HEUFT FinalView II CAP. Compared to HEUFT systems of about ten years ago which only used transmitted light with only one black and white camera, the size of the defects which can be detected on the tamper evidence ring has thus been reduced by a factor of three. Dead angles are no longer an issue and the software update mentioned at the beginning additionally increases the precision of the gapless 360 degree inspection by a good 50 percent.